Computational fluid dynamics – how it’s helping you as a surfboard customer

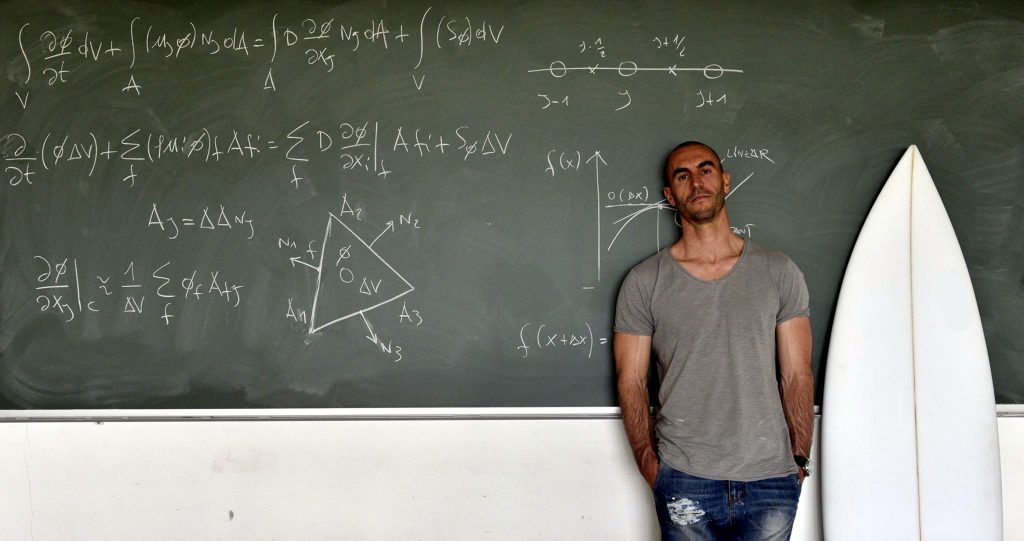

That foam and fiberglass sled beneath your feet, including the fins, just got a whole lot of help from the pocket-protector set. The scientists best known for studying airflow and resistance on rockets, Formula 1 cars and various aircraft, have now turned their attention to surfing. Well, at least one has.

Enter Riccardo Rossi. The 42-

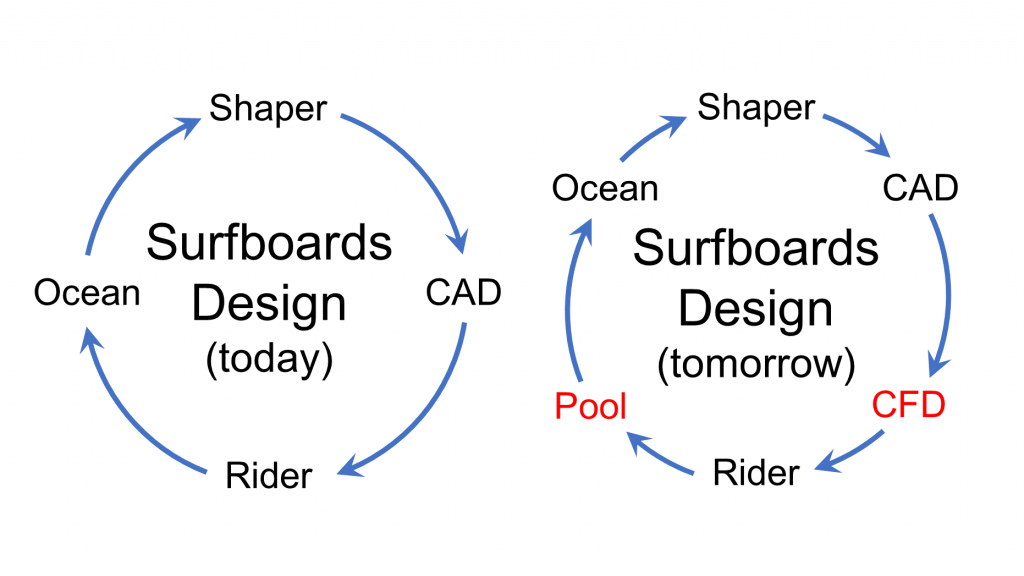

Modeling of surfboard performance via computer fluid dynamics was previously limited. It showed only what should work in theory. These digital tests could then only be supported by a team rider sessioning a new design in a variety of ocean conditions. And then either confirming “oh, yeah mate this board goes unreal” or “nah. Don’t like it.” Not very effective.

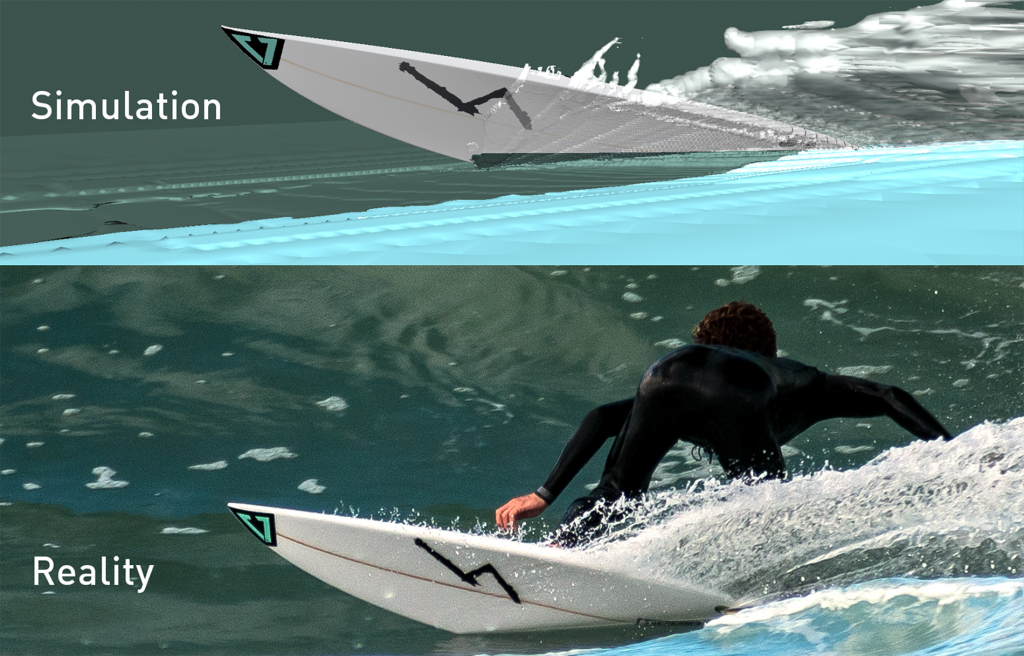

But now, thanks to the wave pool revolution, CFD jockeys like Riccardo and his company Red Fluid Dynamics can map out design performances and then test their designs in a stable environment.

In a nutshell, what is CFD?

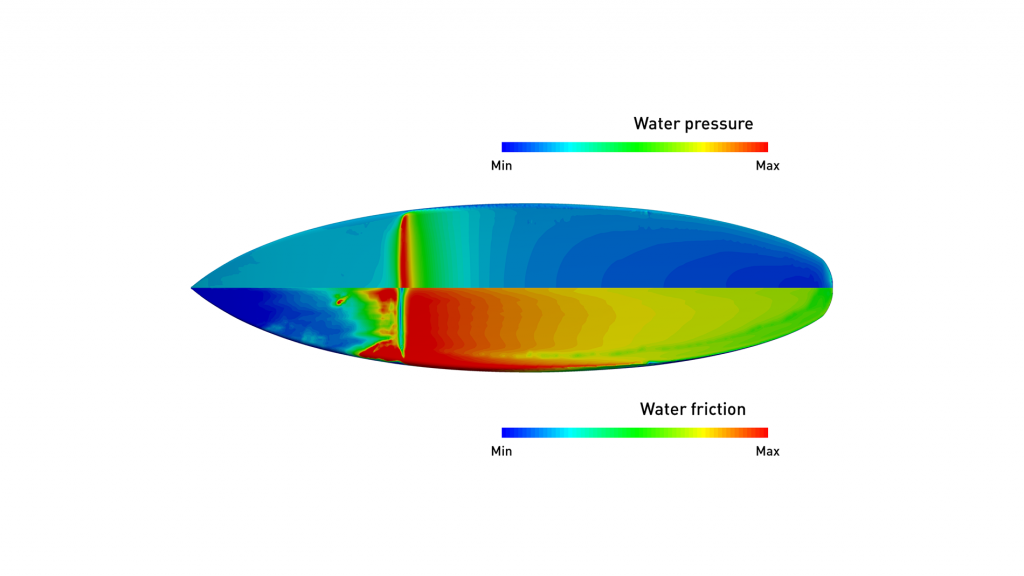

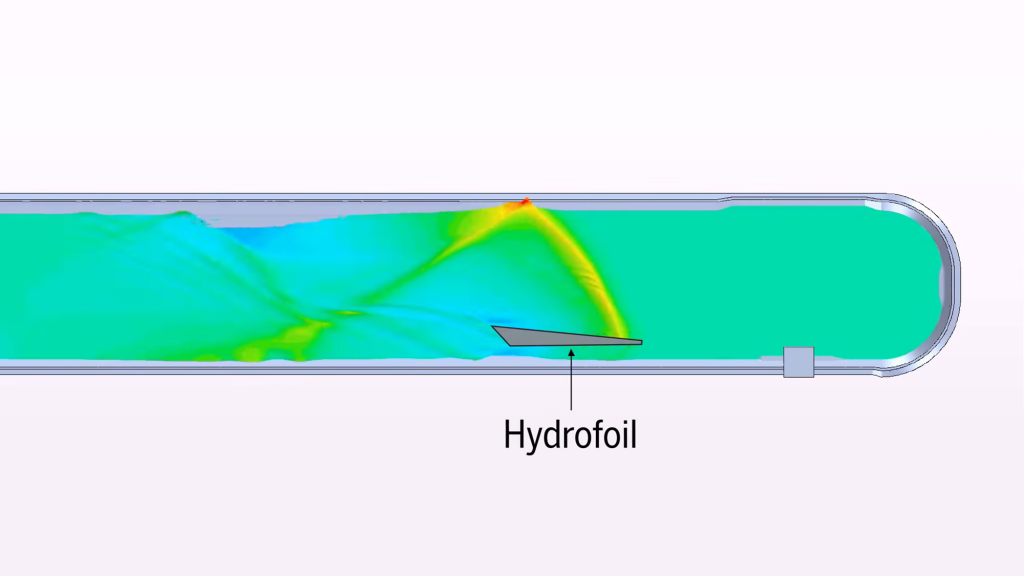

CFD stands for Computational Fluid Dynamics. It’s a technology where the interaction of an object with fluids, like air or water, can be analyzed in a computer thanks to software designed to solve the equations of fluids’ motion, known as the Navier-Stokes equations. You can think of it as a virtual wind tunnel or a virtual towing tank, where designs’ output from CAD software can be tested straight in the CFD software without the need for building the physical prototypes. However, CFD is usually performed along with physical testing to get the deepest understanding possible of the flow and because there are sometimes approximations in the CFD models that cannot be avoided, but there are examples where simulations have almost replaced the experiments. In the America’s Cup, for example, the design of the sophisticated foiled-catamarans used today in competition is performed almost entirely via CFD. The simulations are also used massively in Formula 1, where there is not a single team not relying on the simulations to develop the cars’ aerodynamics in the offseason and to refine it during the championship. And last but not least, CFD is a major foundation of most of the wave pools built to date, including the Surf Ranch and the Surf Lakes prototype pool.

Why hasn’t CFD been used before to design surfboards and surfboards fins?

Back in 2016, when I started working on this project, there were only a few examples restricted to the simulations of fins that could be found in scientific or technical papers and, to the best of my knowledge, none of the major surfboards and surfboards fins companies put an effort in bringing the technology within the design process before. There can be many reasons for this and for sure the complexity of running CFD simulations is one of them. In the case of surfboards, things get even more complex because it is necessary to model the water surface in contact with the air as well as the motion of the board, which is very demanding from the computational point of view. Therefore, such complex models cannot be run, usually, on a simple laptop and require instead the use of supercomputers. If you put all this together, it doesn’t quite fit straight away in the standard operation of a fins or surfboards company. On top of that, the average surfer and the surfing world, in general, has much less focus on technology compared to other sports.

Is this changing in your opinion?

I think so and competition is playing a major role in this, like in many other sports. In MotoGP (the premier class of motorcycle road racing), for example, back in the days was very much like surfing today. There were only a few engineers in a team, no sensors were mounted on the bikes and the setup and tuning during the races were based on the mechanics’ experience, who knew how to make a suspension harder or softer enough by turning a screw, and on the riders’ feedback. Nowadays, each team has a pool of engineers and the bikes are fully instrumented to change the setup and tune the bike based not only on the riders’ feedback but also on data measured during practice. Also, even though aerodynamics has a limited impact on the lap time in MotoGP compared to Formula 1, many teams have now introduced wings developed using CFD models to reduce the bike’s drag and improve stability. The riders on the starting grid are nowadays in fact separated by only a few tenths of second and thus any little improvement on performance counts. In surfing, we won’t probably see a team of engineers traveling with athletes but sensors have been used lately to record data during the surf and we have seen athletes like Michel Bourez testing fins in the Surf Ranch before flying to compete at the J-Bay event. And with CFD, it is now possible to quantify the changes in the performance parameters of the boards, such as drag and lift, due to subtle changes in the design, something which can still make a difference with the competition level going to the roof in the WCT and in view of the upcoming Olympic Games, which will include surfing for the very first time.

Do you think CFD could ever replace the expertise of a shaper?

I don’t think so and for sure not in the near future. CFD is another tool in the hands of the shaper in the same way as CAD software, like Shaper3d or AkuShaper. These programs do not replace the shaper but help him or her instead transform the idea of a new design into the final product. Using CFD, it is possible to test new designs even before starting to cut blanks by simply importing the CAD file in the CFD software. Therefore, it gives the shaper the chance to get an early view of the design performance and to explore many more design ideas in a reduced amount of time. Also, in the CFD model, the board can be split and analyzed in all its main design features, such as the tail, the rails and the bottom contours and for each of them, a separate set of performance parameters can be computed and compared, which is another key advantage offered by the simulations. Very much like Formula 1 cars where there is a strong interaction between all aerodynamic devices and they need to be optimized altogether to perform at best, a surfboard is quite a delicate balance between many different aspects of the design. If you pull the rocker curve too much, you end up having a board that fits nicely in powerful barrels but it’s going to get stuck if you need to go through a flat spot. An experienced shaper knows all this and is able to find that nice balance by experience, but with CFD it is possible to get an even finer balance, because you would not only know that a flatter rocker will reduce drag, but how much it would actually be reduced for a given fraction of an inch taken out of the rocker curve.

You’ve worked with Firewire Surfboards and Futures Fins. What did you do for them?

Firewire was one of the very first companies I made contact with back in 2016 and we have worked together for more than a year, using the CFD technology to analyze some of the iconic models by Daniel “Tomo” Thomson, such as the Vader, the Omni, and the Sci-Fi. From the simulations, we have measured and compared the drag and lift of the boards in planing conditions and during a bottom turn, analyzing the effects of each shape characteristics and how they influenced the performance of the boards. The results were used to validate and provide some guidance for the concepts behind Tomo’s Modern Planing Hull (MPH) theory but also highlighted some interesting and unexpected results. For example, we have found that the double-bat tail of the Sci-Fi, despite its complex shape, leads to lower turbulence and thus to lower drag than the rounded tail of the Omni.

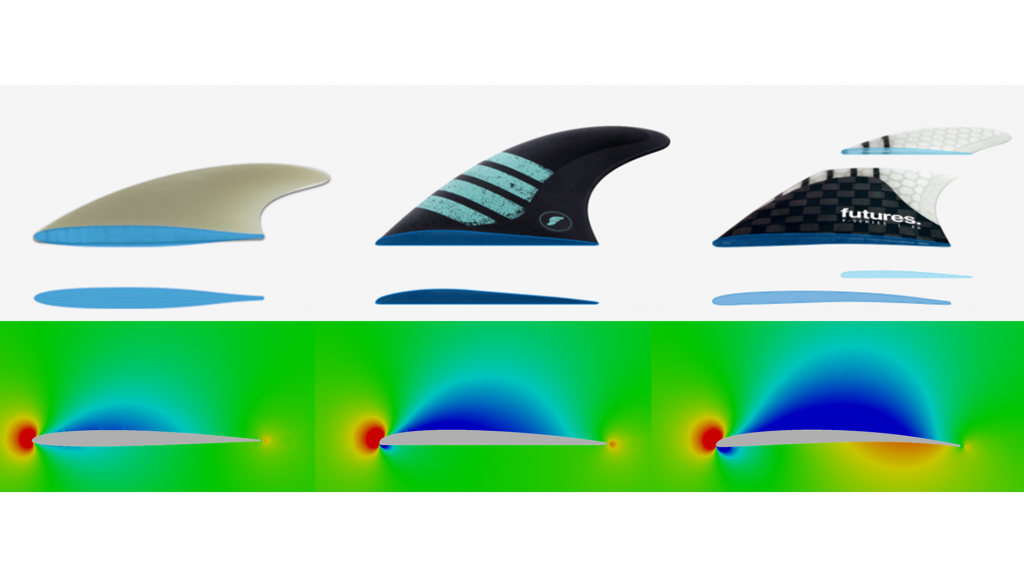

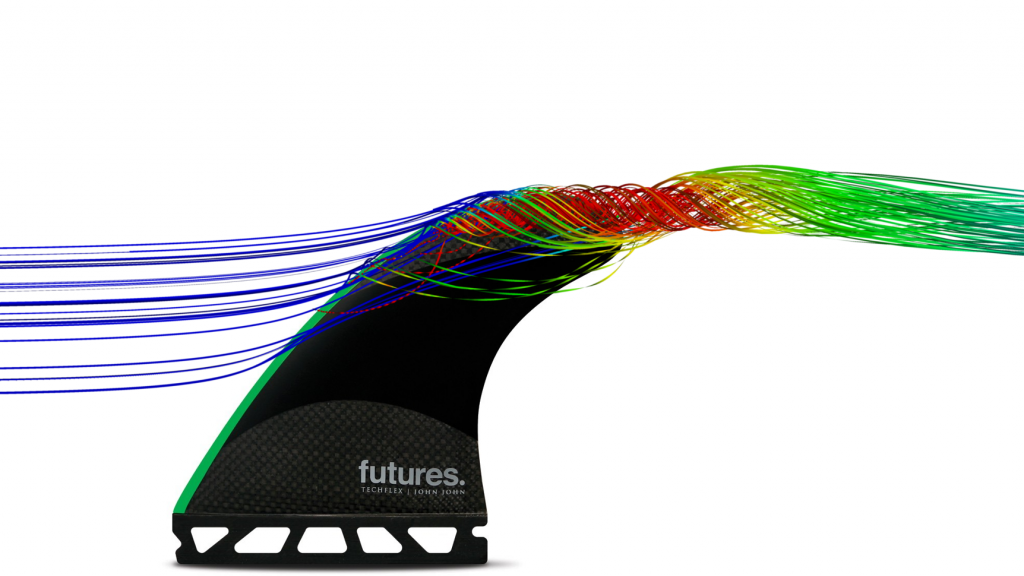

The work with Futures was initially focused on characterizing and quantifying the performance of existing fins on the basis of the various templates, the type of foil and the rake (respectively the shape of the fin seen laterally, the shape of the fin in section and the portion of the fin extending backwards from the base). The foil and rake in particular are two of the main characteristics of the fins that together with the flex (the flexibility of the fin, which varies depending on the thickness and the material) determine the Ride Number, an index that varies between 1 and 10 introduced by Futures to facilitate the choice of fins by the surfers. For lower values (1-3), the ride number indicates fins designed for large and powerful waves, while for high values (7-10) fins designed for smaller and less powerful waves. Thanks to the CFD technology, we have been able to quantify the relative difference in terms of drag and lift between foils and rakes to better understand the effect of the main characteristics of the fins on performance.

Also, I’d like to mention an Italian company, Sequoia Surfboards, with which we established a partnership at the same time the collaboration with Firewire was kicked off. Since then we have been running CFD models of each board released in the market and also developed from scratch a high- performance hybrid model, the Enzo, named after Ferrari’s founder Enzo Ferrari. Using the CFD technology, we have refined through several iterations between the CAD and the CFD model some of the main features of the design, such as the bottom contours and the outline, and the board has been a major success and it is still a top seller throughout the Peninsula.

How can wave pools serve as a testing ground for developing boards, fins and other equipment? – could you test drag on a pair of board shorts?

Wave pools have one characteristic that is key when it comes to boards and fins development: repetition. Testing surf equipment straight in the ocean, where conditions are everchanging, it’s like testing a car in a racetrack where corners change radius and direction during each lap, making way harder for the driver to feel and tell what one change in the setup of the car is doing. Likewise, it is very difficult to dissect the differences between surfboards and fins designs by taking the board out only in the ocean, especially when it comes to subtle changes unless you have perfect J-bay or Trestles next door on a daily basis. In a wave pool, on the other hand, you can perform the same maneuver over and over on the same type of wave and this gives the surfer the chance to better feel what’s going on under his feet. Wave pools thus represent the perfect ground for initial testing of boards and fins and will also be key in the process of validating and advancing the CFD technology by evaluating simulations results based on feelings in the (fresh) water.

And what are your thoughts concerning some of the critics towards wave pools being a very different environment from the ocean, and therefore not a reliable testing ground?

There are of course many differences between surfing in a wave pool and surfing in the ocean and in the same way CFD is not going to replace the shapers, artificial waves will not replace entirely the natural waves, even when it comes to testing equipment only. These technologies will be complementary to the existing design and development process of boards and fins and the final testing will always be performed in the ocean, where all the variables come into play. Even in F1, where CFD models and wind tunnels are far more mature, the cars are developed using simulation and testing setups which cannot replicate the actual conditions occurring during a race, but they are used to understand and evaluate the basic characteristics of the car’s aerodynamics which will form the basis of aerodynamics performance on track. Likewise, CFD and wave pools technologies can be used to analyze and refine the basic hydrodynamics characteristics of boards and fins in a controlled and repeatable environment, where it’s possible to compare consistently design changes, before moving to the unpredictable and ever-changing environment, the ocean.

Is there a discrepancy between what you see in computer simulations and what the surfer feels underfoot? Meaning, will the computer model show a design characteristic and a surfer like Kelly won’t feel the same thing that the computer is showing?

When we deal with design characteristics having a significant impact on performance, such as the rocker curve for the boards and the foil for the fins, we always had a good correlation between feelings in the water and simulation results. For example, a quarter of an inch reduction in the tail rocker can give up to 35% difference in dynamic lift and flat versus curved foils can lead to 15% difference in lateral force on average during a bottom turn, with peaks as high as 20% when the turn is initiated. Therefore, even when testing the boards and fins in not ideal conditions it is possible to feel those differences. But when it comes to more subtle changes, there is definitely a gap between the precision of simulation results and the sensitivity of the surfer and this is where wave pool can make a huge difference.

If you got to design a wave pool specifically for testing fins, boards and other equipment, what would it look like?

As long as we are interested in the pure hydrodynamic performance, anything able to produce a wave like the one of the Surf Ranch. The reason for it is that you need some power from the wave in order to get to the planing speed, where the dynamic lift is large enough to make the board fully skim through the water. At that point, only the board design matter and other characteristics, such as the volume of the board, do not affect performance anymore. This is also why surfing in freshwater only makes a difference in less powerful wave pools, such as the BSR Surf Resort, where the speed more often falls below the planing limit and thus board volume and water density come into play. Ideally, it would be best, of course, to be able to test the equipment in both powerful and weaker waves, in order to get the most comprehensive picture.

I’m pretty happy with my current quiver. Are surfboards the best that they can be at this point in time? Or is there room for improvement for the average surfer?

No, I believe there is still room for improvement, especially if technologies like CFD and wave pools will spread and extensively become part of the design and development process of boards and fins. Citing Matt Biolos from one of your interviews “it’s a slow process” that innovation can speed up.

Trackback from your site.

Related Coverage