Board Science! Epoxy vs. Polyurethane builds for wave pool domination

Polyurethane foam and fiberglass is cheap, abundant and has become the standard for surfboard construction. It’s been that way for almost 60 years now. Every other aspect of surfing gear has made technological leaps and bounds: fins, leashes, boardshorts and wetsuits. But surfboard materials remain the same.

PU is toxic and, relative to other materials, not so strong. There are options in the marketplace for a better build, constructions that are both lighter and stronger: EPS and epoxy; Firewire’s constructions and a few other emerging technologies like LibTech.

All of these offer superior strength-to-weight ratios. But PU is very, very familiar. For that reason, most all new surfboard-construction materials are compared to PU for performance.

We’ve all had that one magic polyurethane-constructed board, a board with flex properties that work perfectly for us. But PU flex properties vary from board to board due to a variety of factors: glassing, sanding, foam density and of course – wood stringer density. Plus, PU has a shelf life. A board will surf differently after 6 months than it did right off the shop racks.

Jason Koons of Superbrand explains: “All of the structural support for PU is in the 0 and 90-degree directions (parallel and perpendicular to the stringer)” says Koons. “The results are somewhat predictable, but with fluctuations in foam density and stringer grain the results for two boards shaped exactly the same can vary to a frustrating degree at the highest level of surfing.”

Epoxy is fast becoming the construction of choice in the wave pool world. Matt Biolos says he kits out his team in epoxy for wave pools like Waco, especially during the Stab High event.

So how do PU and Epoxy perform when compared to each other? What if we tested PU and Structural EPS against each other? Well, we did. And here’s what we discovered.

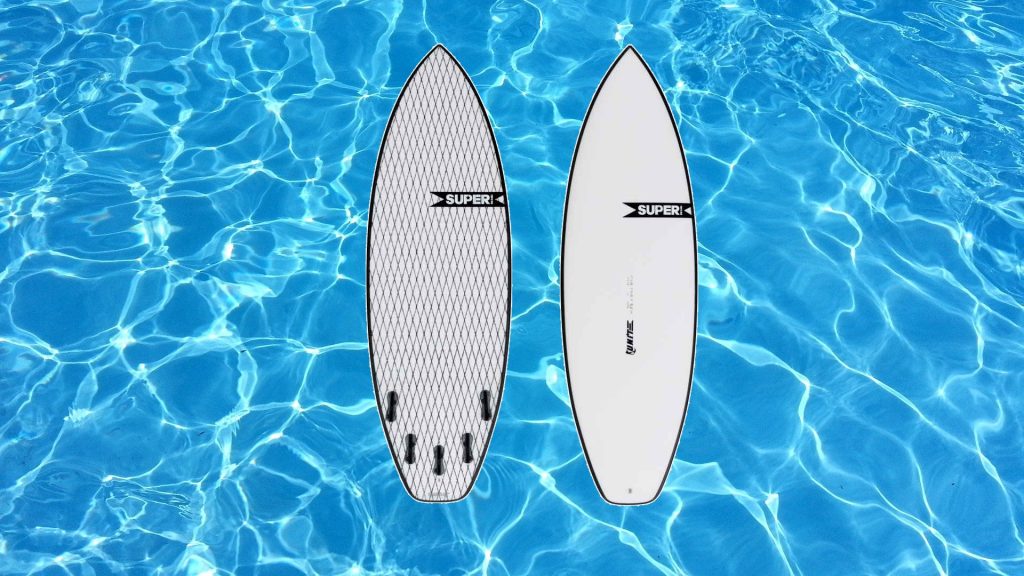

In this review we tested the same board, an old SuperBrand 5’10” Unit with the following dims: 20 1/2 x 2 5/8 at 33.5 Cubic Liters. We rode both boards with the same fin setup: Futures V2 JC1 Black Stix. The board tester is 6’1” and 190 lbs with an advanced skill level but not an expert surfer.

Board #1 in Polyurethane: The very same materials and construction surfboard makers have been using for around 60 years—polyurethane foam with a wood stringer running down the center.

Board #2 in EPS: Jason Koons claims the stringer-less eps core blanks are super predictable in flex and yield nearly the exact same results every time between two blanks. “Because the core has a consistent density from board to board and the multilayered glassing schedule is multidirectional we get a light predictable controlled product,” he added.

Glassing

Board #1.) Polyurethane: The magic PU board is glassed with one layer of fiberglass S-cloth on the bottom and two layers on the top and set with polyester resin.

Board #2.) Superflex: Glassed with a layer of glass that has additional strands following the nose-to-tail direction called Warp glass. Think of it as going with the grain in wood instead of against it. Then they add Vectornet (the net-looking stuff on the bottom) which adds strength and controls flex further.

What We Discovered

Polyurethane: We liked the PU board best for performance, liveliness and responsiveness. The board’s flex properties were amazing and familiar. There’s just something about the ‘zing’ you get from the first pump off the back-end of a PU board. Paying close attention we could feel the board twist and spring out of turns – think about it, we apply different levels of pressure to the front foot and back foot when pumping down the line.

That said, there are a variety of factors contributing to this PU board performing this way: blank density, stringer density, how the rails were sanded and so forth. Had I picked up the exact same board model (polyurethane, same dimensions, cubic liters, etc) it would ride differently and may or may not qualify for ‘Magic Board’ status as this one did.

One thing is for certain though, we did not like how fragile the PU construction is. In just a few months we’ve busted out a fin, creased the forward part of the board and smashed the tip of the test board. Something to consider if you’re banging your stick around a surf park.

Structural EPS: On a basic level it surfed lively and well. Conversely, it did feel a tad stiffer flex-wise and didn’t quite knife through the water as well as it’s PU counterpart. It was more prone to skip out when turning hard off the tail, more so than the PU version.

For fifty percent of the sessions, the Superflex board went fine. It worked better than the PU board in smaller, gutless surf. The other sessions it didn’t quite have that magic ‘zing’. This was more the case in bumpy surf. It felt more floaty than the PU.

The Takeaway

Polyurethane performs, but you never know what you’ll get off the rack with two identical models with identical dimensions due to inconsistencies in PU blanks and the laminating process. If you get a magic PU board, “keep it on ice” as one industry insider has told us. Also, consider the environmental impact of PU which relies on more petroleum products to produce than epoxy does. This factor is compounded if you damage and shorten the lifespan of stick due to excessive wave pool use. All surfboards ultimately end up in the landfill.

The EPS is durable, light and better-suited to smaller surf. It’s more floaty due to reduced weight which helps in freshwater wave pools. It’s also more durable. The encounters you have in a wave pool are with concrete instead of sand, so you rack up dings fairly fast.

So do we have a winner? For wave pools, we’d give the nod to epoxy construction, especially when made with a carbon wrap for engineered flex. Epoxy’s durability, snap, response, float and predictability make it a great choice for wave pools without the environmental hangover.

If you want to venture further down the rabbit hole of board construction, check out Noel Salas in the clip below as he samples five boards in different constructions…

Related Coverage