Coming up Disney: Designing the pump and dump at Typhoon Lagoon

The great thing about wave pools is that with such a short history – just 15 years, well, 30 and 50 respectively if you count Typhoon Lagoon and Big Surf – you’d think there’d be very few mysteries stashed away on microfilm in some exotic city. But thankfully life is full of surprises.

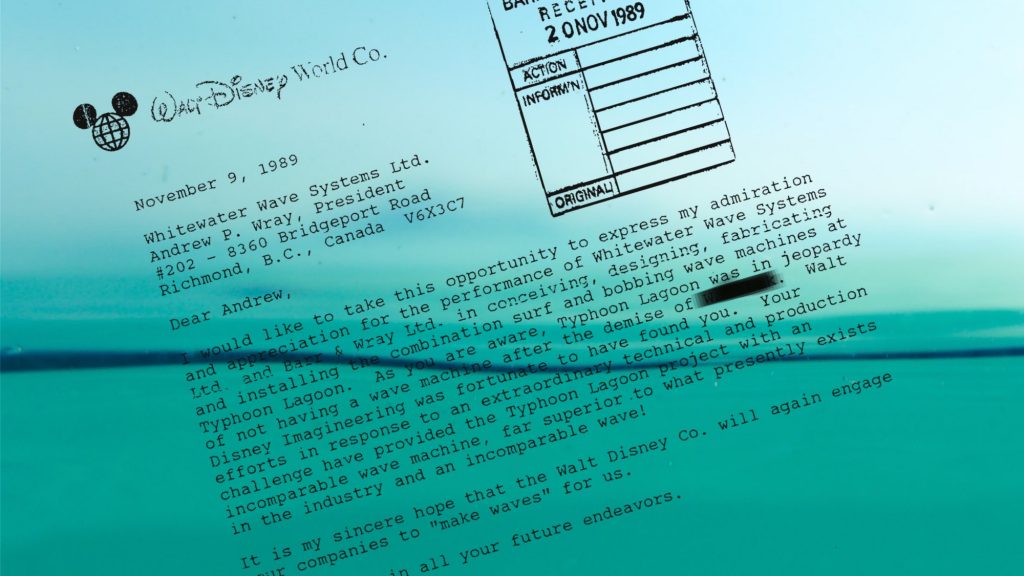

We received an email informing us that the hydraulic wave system for Typhoon Lagoon and several other wave pools like Sun City South Africa was designed by Barr+Wray with help of a test tank at Edinburgh University. The email was a bit cryptic, like jumping midway into a conversation but then most emails we get are like that.

How should we play this? Do we blow it up Beachgrit-style and blame the WSL for ruining surfing? Or do we drill down the details on the system’s caissons until the story is interesting to just a handful of engineers and the one guy who stationed the water pumps back in the summer of 1990?

We took the easy route and fired straight back to Derek Barton of Scotland’s Barr+Wray to get more of the story. According to their website, Barr+Wray designs spas, leisure pools and “wave machines for surf pools.” In the 1980s Disney approached Whitewater (makers of Endless Surf) and Barr+Wray to create Typhoon Lagoon.

Derek warned us that much of his story was second hand, but still solid. He even provided us with pdfs and some business ledger stuff we didn’t quite understand. And it turned out that Typhoon Lagoon’s backstory was in fact stashed away in a filing cabinet in a far-away city – in this case, Glasgow. But the story only really came to life in the gregarious banter of Mr. Barton’s emails. WavePoolMag learned how the system works, why it’s still much loved and what it’s like working for a demanding beast like Disney.

Typhoon Lagoon is similar to Big Surf in Arizona, like a giant toilet tank correct?

Absolutely, the water is suspended and hydraulically dumped, which actually replicates the way in which a Tsunami is created with either a displacement from subterranean land movement or displacement with a landslide, thereby lifting the water which makes it travel in the same direction as the movement/displacement. I was actually at Typhoon lagoon one day, and this big US lad slapped me on the back and asked if I had figured out how that thing worked yet. He was stunned when I told him my company had designed and built it!

Had the companies done a wave pool like this before? Did Disney want the wave to be surf-able?

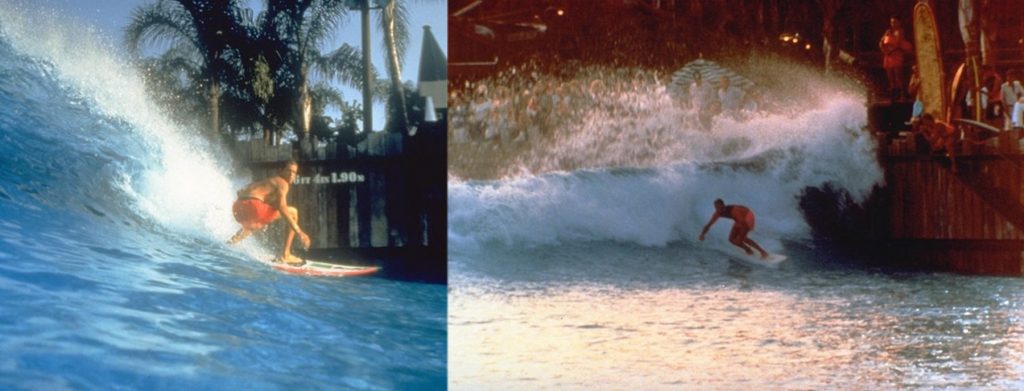

Yes, the pool had to be surf-able, and no, no-one had made one like this. Surf machines were pneumatic and if the wave height was to be larger for body surfing, the caissons had to be staggered, so that the first set of waves were then added to at the correct time with the second set of chambers and so on. This meant that strangely shaped pools and multi-pattern wave generators, which are preferred for leisure pool bathing, then don’t really work.

In the late ‘90s at conventions like IAAPA, all the surfers loved Typhoon Lagoon and what was created. But these were leisure parks with bathers footing the bill.

How did you design it without CFD or CAD? I mean, was it all sketched out on napkins then to draft paper?

CAD was in its infancy, certainly for companies our size and so most of the drawings which we still have, are on paper format. This is just how it was done.

Did you build a small-scale prototype beforehand?

We engaged Edinburgh University to model the wave unit making sure that with their test tank, we could simulate the ‘dump’ effect to create the water displacement allowing for the wave to then travel the length of the pool tank, as opposed to the pneumatic system which is an oscillating wave.

Any stories about the technology Edinburgh was using to develop the system?

From what I gather, the principle (design theory) had always been sound, the trick was to create the mechanism to do so. This is what Barr+Wray developed with the Edinburgh Tank used to show that the elevation of the water and quick release created the displacement and allowed the wave to travel toward the end of the pool. Barr+Wray developed and constructed the machine. However, as Whitewater had the US market and we were working together at the time with Whitewater in the US market (B+W were not active there without Whitewater), it was decided that Whitewater and B+W would take out a joint US patient to cover the development. Unfortunately, most parks proceeded with pneumatic machines and the surf market did not really take off until early 2010s.

You mentioned a “demanding client” would you care to elaborate?

Come on, it’s Disney. We were a small engineering firm in Glasgow, Scotland. This was Disney!!! From what I am told, there was a Disney employee seconded to Glasgow to work with the team so they were overseeing the works. Could all be folklore though!

Did you ever think the wave pool space would become what it is today?

It’s amazing, when we were promoting Typhoon Lagoon, Sun City, Sunway Lagoon and Caribbean Bay, in the late ‘90s at conventions like IAAPA, all the surfers loved Typhoon Lagoon and what was created. But these were leisure parks with bathers footing the bill. The fact that the surf market has boomed with these inland surf parks which are varied in technologies and offerings, is just fantastic. I am incredibly proud of the engineering capability which our company has, past and present projects have allowed us to create fantastic developments and experiences. Typhoon Lagoon still stands today, over 30 years on still pleasing the crowd, the original and best.

Editor’s Note: Whitewater worked extensively with Barr + Wray to make Typhoon Lagoon happen. As Andrew Wray told us in an email: “B&W were very much an engineering company and did not have the ability to contract in the United States. Whitewater had the resources to do the electrical design and supply as well as the hydraulic systems. We were also happy to contract the work and had the resources to look after the installation and commissioning. The project was very much a joint effort and would not have happened without both parties at the table.”

Related Coverage