Ditch the Concrete: Endless Surf partners with innovative steel pool construct

Exclusive pool construction for Endless Surf customers is all stainless steel and uses no concrete. System offers a solution for surf parks with high-water tables, soft soil types and harsh environments. Both companies say the pre-fabricated modular design eliminates construction errors and results in faster-finished projects.

Endless Surf announced a partnership this week with Myrtha Pools to help alleviate many of the common challenges that surf park developers face when constructing and operating a surf lagoon. With the new partnership, Endless Surf will have exclusive access to the state-of-the-art Myrtha Pools stainless steel pool technology.

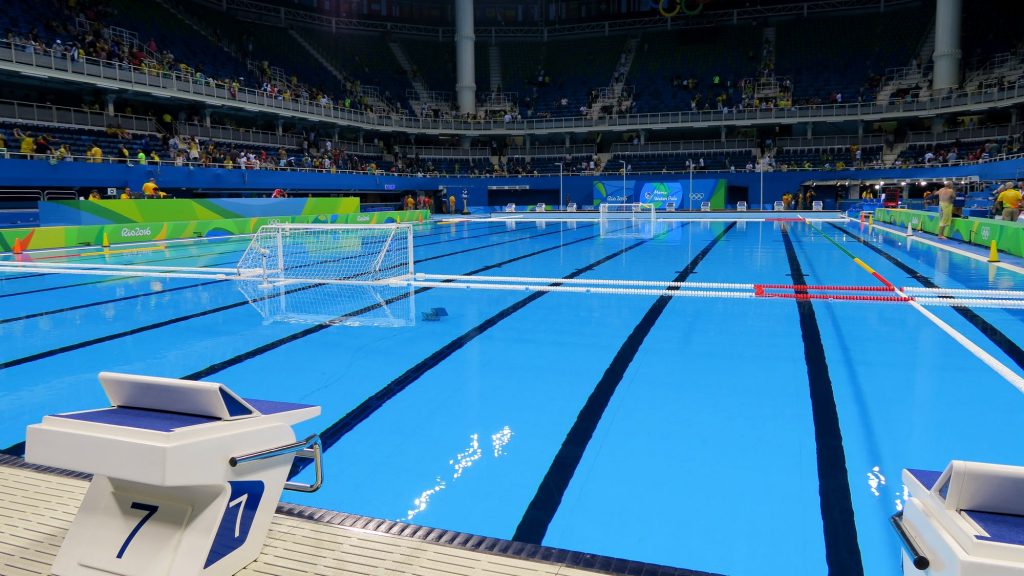

Myrtha’s entry into the surf pool space draws on the company’s decades of pool building experience for world-renowned resort and leisure developments. Myrtha is also well-known for its work on Olympic competition swimming pools.

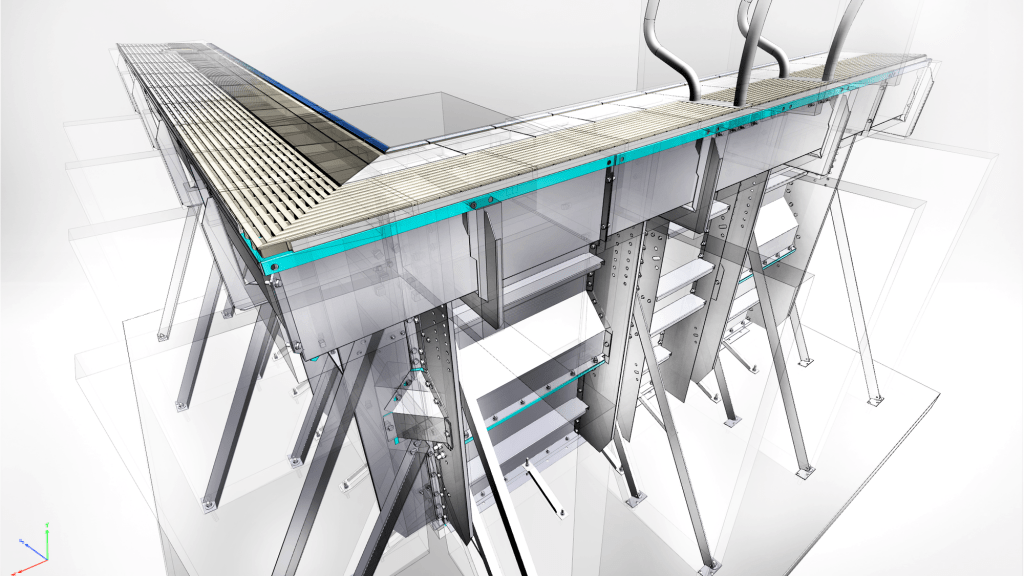

Rather than using concrete, Myrtha Pools are comprised of stainless steel with laminated PVC. The company says this translates to a cost-effective, long-lasting, and much more sustainable solution to many lagoon construction problems. To back up just how durable the technology is, Myrtha also offers a 25-year warranty with their builds.

“As many of our Endless Surf projects are starting to enter construction phases, we are thrilled about our new partnership with Myrtha Pools and all the benefits it brings to our clients and their developments,” said Endless Surf President Paul Chutter. “At Endless Surf, we are focused on offering a product that delivers and lasts a lifetime without having to address maintenance issues down the line. Having a pool-building partner with the same relentless commitment to innovation is a must. Plus with Myrtha’s history in competitive sports at the highest level, this partnership in surf is a no-brainer.”

Endless Surf said the partnership came about after seeing issues with surf lagoon construction.

“Issues are becoming more and more common, with many problems arising well into the operating phase, causing lengthy downtime and pool closures,” added Chutter. “Problems with liners, cracking/splitting concrete, and leaks are becoming common, and this new partnership between the two companies that have a collective experience of over 100 years in the aquatic entertainment space aims to eliminate these headaches that developers face.”

Myrtha Pools said their durable pool construction paired with the reliability and redundancy that is built into the Endless Surf system makes having to drain the pool for maintenance an anomaly, ensuring smooth operations year-round.

“We’re so proud to provide our products and solutions to Endless Surf projects as we enter the surf park space with them,” said Roberto Colletto, CEO of Myrtha Pools. “With our Myrtha Pools technology – and more than 60 years of history and innovation – the Endless Surf lagoon is guaranteed to be waterproof, sustainable and long-lasting. This partnership brings to the surf park the most advanced solutions for reducing the impact on the environment while delivering natural and aesthetic traits, and to out-perform other technologies over the long run.”

In addition to providing the shapes and contours for the surf lagoon, Myrtha’s engineers are also contributing design solutions to the pneumatic caisson framework, the chambers responsible for generating waves. This idea only adds to the efficiency and unity of Myrtha’s contribution to the Endless Surf concept.

Both companies said that their innovative spirit and history will better the surf park industry as a collective.

“This partnership is exciting news for the surf park industry with both companies demonstrating their drive to deliver inland surf experiences that are viable and sustainable as businesses,” added Colletto.

Related Coverage