2024 Surfboard construction options for wave pool rental fleets

Choosing the construction of your surfboard pre-Gidget era was simple: it was wood . . or wood. The chemical code for polyurethane foam (better known as PU) was cracked during World War II by the Germans, seeking a replacement for rubber, and it was introduced to the nascent world of surfboard manufacturers in the late ’50s. Compared to wood, PU is lighter and easier to work with, and PU has remained the dominant material for surfboard blanks since.

But humanity is never satisfied with the status quo, least of all surfers. Seeking materials that are lighter and stronger, boards are made of or wrapped with a combination of everything from carbon fiber to plastics/epoxy, kevlar to aerospace composites. All this aims for the surfboard Holy-Grail characteristics of exceptional durability, lightweight, and responsiveness.

While all this reaching-for-the-stars surfboard science is great, the key is simply having a light and strong board. And while this is relevant for all surfers, no matter where in the world they’re heading out for a paddle, it’s never more apt than for surfing in wave pools. Surfing close to concrete walls and floors, it’s inevitable that boards will repeatedly come into contact with them, so durability is key.

All wave pools offer a selection of hire boards but due to the rigors they can be subjected to, they must be of the highest quality and appeal to a wide range of surfers. Surfboards hired at wave pools likely spend more time on waves than those at regular surf resorts and camps; they’re constantly in high rotation. Some of the world’s best shapers have realized this and have developed tech that balances strength, weight, and responsiveness.

WavePoolMag reached out to several board makers to list construction techniques that work best for surf park rental fleets. Chances are you will find these surfboard constructions at the rental shop during your next wave pool session.

LIB Tech

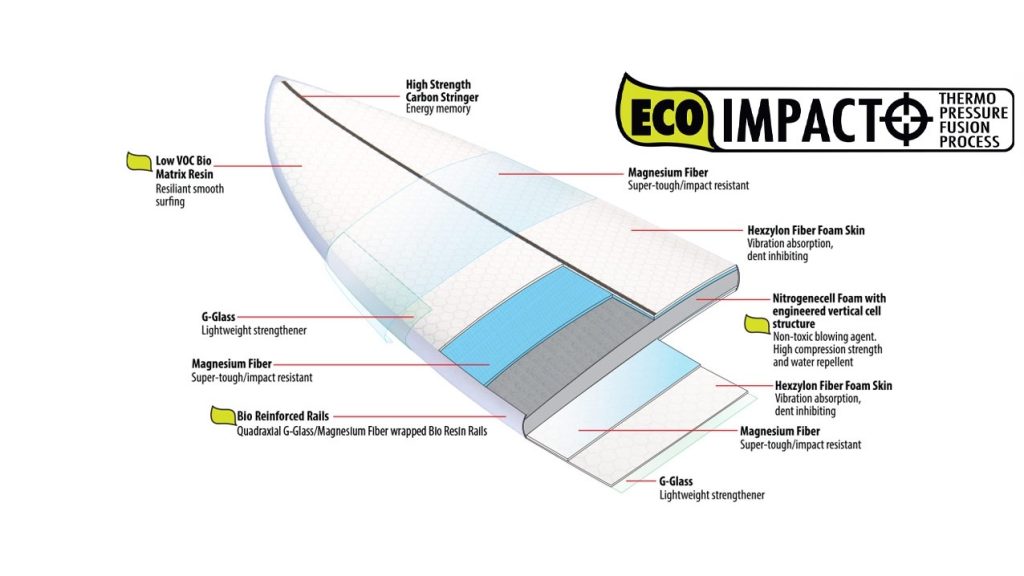

LIB Tech is a board construction technology used most prolifically by LOST Surfboards, incorporating carbon stringers, plant-based resin, magnesium fibers, and nitrogen cell upcycled foam. “We have LIB Techs in demo fleets at multiple wave pools,” said LOST’s Matt Biolos.

Suitable for surf parks, the foam core is Nitrogencell, a closed-cell foam (it won’t absorb water) with an elongated cell structure that claims to be better for compression strength and energy return. To give the foam additional properties of flex memory and energy return, Lib Tech loads the cells with nitrogen. Nitrogencell is also made of 25%- 50% recycled material—FYI; Lib Tech also recycles 100% of the offcuts into new foam.

LOST also has rental/demo boards in Black Sheep and LightSpeed tech available at Waco, Palm Springs Surf Club, and Surf Stadium in Japan. The Black Sheep tech utilizes a 1.5lb epoxy foam blank (EPS) with ‘Triax’ Carbon laminated only on the deck, with a short bottom lap and sandwiched with multiple layers of 4oz, for both durability and performance. According to LOST, it’s engineered for rapid reaction to maintain a forgiving flex and dampened overall feel underfoot.

On the plus side, they’re incredibly strong and light, but as it’s a carbon fiber board (I.e., black), they can heat up quickly if left in the sun, but according to LOST, are still built to take “day to day bumps and bruises very well.”

The heart of the LightSpeed boards features an ultra-light, high strength-to-weight ratio, fused cell, water-resistant, stringer-less EPS foam core. Add to this the use of an impact-resistant epoxy resin system and a carbon fiber centreline ‘stringer’ (top and bottom), and you have a light and highly responsive board fit for the pros.

XTR Epoxy

XTR is another epoxy foam technology that is currently being used by over a dozen of the world’s leading board companies, from Pyzel to Sharp Eye, Channel Islands to LOST. Based in California, XTR produces 100% waterproof closed-cell eXTRuded foam – get it?

“Given the rigorous daily use and impact experienced in wave pools, our boards’ durability and waterproof nature ensures . . . maximum time spent in the water, benefiting wave pool operators,” said XTR’s Shey Yates.

Shey added that compared to traditional PU foam construction, XTR offers a performance advantage with light, durable, and lively boards, providing exceptional speed, drive, and pop. “They maintain the true feel of polyurethane while eliminating the chatter often associated with Epoxy/EPS boards,” he added.

Thanks to the magic of computer files and the efficiency of shaping machines, XTR has an extensive catalog of over 300 boards from 13 shapers they produce onsite and under license. Are you keen on a Pyzel Ghost?, a LOST Driver 2.0?, an Album Twinsman, or a Channel Islands Two Happy? Order away. In addition to the XTR Epoxy Technology, boards can be built with traditional wooden or carbon fiber filament composite stringers, achieving different flex standards. Add to this the choice of glassing – XTR team, XTR light, XTR standard – and you can customize your board’s drive and responsiveness.

Volcanic Lamination by Firewire

Firewire’s Volcanic Lamination is a newer tech that can be found at several wave pools, and sometimes under the arm of that evergreen GOAT, Kelly Slater.

“We call it “Volcanic” Lamination because the fabric we use is derived from basalt rocks that come from the rapid cooling of lava after it breaches the earth’s surface,” said Firewire’s Chris Grow. “These rocks are melted down and extruded into woven fibers. The basalt cloth is then laminated around either our Helium or I-Bolic Core Technologies.”

Firewire regards its Volcanic Lamination process as creating an elevated response and increased durability above traditional laminations. “This is why we recommend it for wave pool rental fleets,” said Chris.

As you’d likely expect with the Firewire/Slater/Surf Ranch connection, there is a quiver of shapes with Volcanic Lamination currently at the Surf Ranch, “and we’re looking forward to building out more Volcanic Lamination quivers at wave parks throughout the U.S., Europe, and Australia.”

Firewire has fleets of boards at other parks and is in the process of updating them to offer shapes in the newer Volcanic Lamination technology.

Rental fleets are a big investment for surf parks that, if chosen correctly, quickly pay for themselves. Whether you’re building a fleet of boards for your wave pool or are looking for the longest-lasting, highest-performing board for pool sessions at your local, there are plenty of cutting-edge options out there.

Bell Surfing

Stephen Bell or simply “Belly”, familiar to all webcast viewers as Kelly Slater’s confidant extraordinaire, runs Bell Surfing. To expand the brand’s roster of shapers, Christiaan Bradley, Mark Phipps and Phil Grace beyond the beach to the wave pool, Bell Surfing will launch a unique program with five new construction technologies. Each pool-friendly construction intersects with a surfer’s skill level and board performance demands.

The five different Bell wave pool constructions (Hybrid, Surf Ease, Carbon Inner, Resilient Tech, Carbon Bonding) correspond to the board models best suited for a particular level of surfing. As such the Hybrid tech comes in Egg shapes and the Carbon Bonding comes in high-performance shortboard models.

Bell’s Full Carbon Bonding Technology is aimed at precision performance and extended durability. This construction method utilizes Japanese woven 160g multi-directional carbon fiber, 4oz E-Cloth fiberglass, a 36g EPS core, and aerospace-grade epoxy resin to create a lightweight yet strong structure. The technology is designed to maintain optimal flex patterns, provide rapid energy transfer for speed generation, and offer a lightweight, high-performance build suitable for competitive surfers and enthusiasts alike.

Resilient Tech construction uses aerospace-grade materials and innovative design to enhance surfing performance. The Sandwich Board Technology features an aerospace-grade resin and composite deck for durability and a lightweight profile. A carbon T-stringer system mimics traditional polyurethane board flex patterns while internal carbon fiber components offer flex control and strength. A 3 mm aeronautic-grade deck skin protects the core without compromising flexibility. The combination of carbon fiber and fiberglass in the deck, bottom, and rails ensures enhanced durability and longevity compared to traditional boards.

Bell’s Carbon Innegra Bonding Technology combines carbon fiber, Innegra, and a robust EPS 36-degree blank core to create lightweight, strong, and durable surfboards. Innegra fibers enhance impact resistance to reduce damage risk. The high-density EPS 35-degree blank core ensures stability and optimal shaping for a strong and responsive board. Custom Carbon-Innegra tape reinforces the rails and outline, protecting against wear and increasing flexibility to enhance energy return and control while surfing.

Surf Ease Technology offers a blend of durability and sustainability and features user-friendly and rounded shapes that simplify wave catching and maneuvering. The technology supports surfers’ growth with a design that boosts confidence and facilitates progression. The boards are equipped with a specially designed 36-gram molded blank for resistance and buoyancy, Sicomin 56green epoxy resin with 56% bio-based content for sustainability and performance, reinforced fiberglass layering for flexibility and rigidity. Surf Ease also uses Bell’s durable leash plug and the Futures fin system.

Bell’s Super EPS Hybrid Technology is suitable for beginners, rental businesses, and regular wave pool visitors. The core of the technology features a lightweight 36-degree expanded polystyrene (EPS) core known for its lightness and durability while the deck is reinforced with dual-layer glassing, including two layers of 4-ounce fiberglass for enhanced durability and agile responsiveness. A 3mm Thermoform soft covering on the deck and rails offers a comfortable grip, crucial for new surfers and continuous use in rental settings. The slick bottom design minimizes drag while the carbon T-Stringer provides structured flexibility and controlled flex to maintain the board’s shape under varied pressures.

Related Coverage