Wave pools and CFD push fin design forward

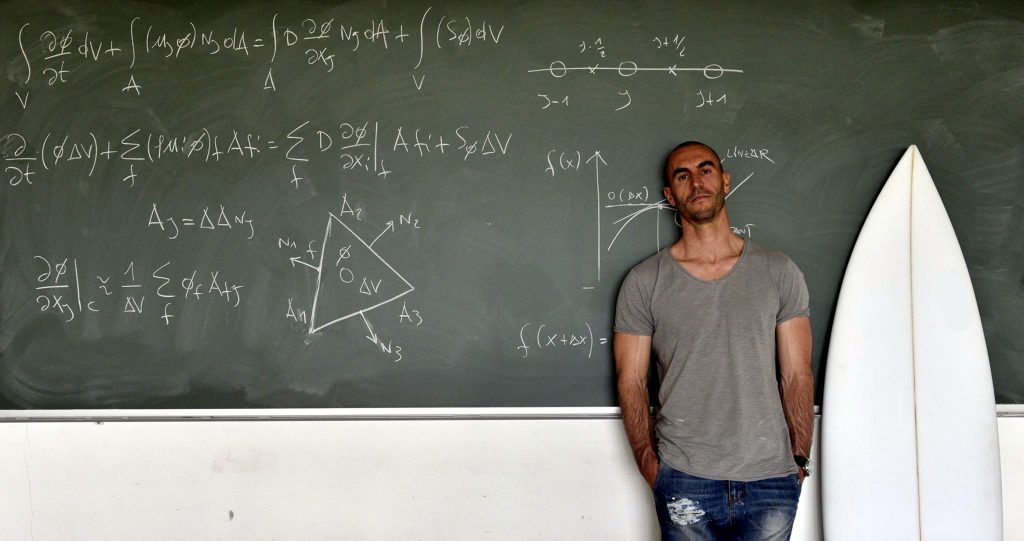

Riccardo Rossi, or simply “Ricky” to his American colleagues, is leading the integration of computational fluid dynamics (CFD) simulations into surfboard and fin design. And he’s tapping wave pools to do it.

Previously, wave-riding tech relied on team riders to validate designs through a variety of ocean conditions. However, the repetition of human-made waves allow CFD experts like Ricky to put their findings to a somewhat controlled testing environment.

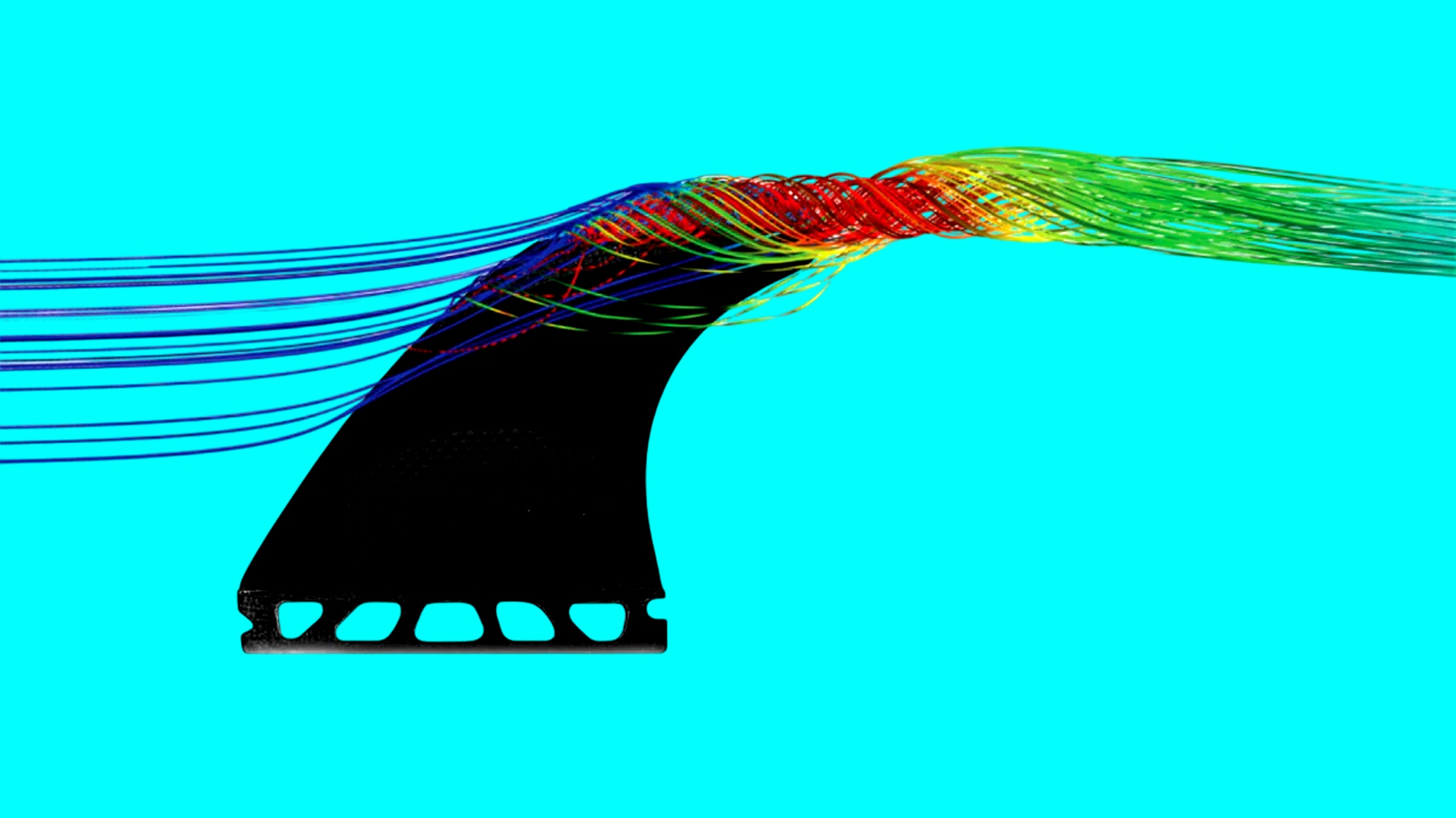

How it works

The field of Computational Fluid Dynamics develops numerical models and digital twins of products and processes. These numerical models and digital twins allow a visual and computational mapping of fluid flows and related transport phenomena which is then used in a broad spectrum of applications. This includes everything from vehicle aerodynamics to soccer balls. The process is even used in therapeutic aerosols and their delivery of medication into the human lungs.

Ricky said the process in a surf-focused is just as complicated, but helps developers understand basic characteristics of water flow even before a product gets wet.

“In the surfing world we have worked with Firewire, Dakine and Futures using CFD to support expertise and experience in designing new products with a tool able to provide a comparative assessment of performance in a controlled environment,” said Ricky. “This provides numbers on top of “feelings” for a more comprehensive, and scientific, development of surfing gear.”

Wave pools offer a key advantage for board and fin development: repetition. Ricky says that testing surf equipment in the ocean, where conditions constantly change, is akin to testing a car on a racetrack with shifting corners, making it difficult for drivers to assess the impact of setup changes. Similarly, evaluating surfboard and fin designs in the ocean complicates the detection of subtle differences, unless you have perfect conditions like J-Bay or Trestles available daily.

“In a wave pool, on the other hand, you can perform the same maneuver over and over on the same type of wave and this gives the surfer the chance to better feel what’s going on under his feet,” said Ricky. “Wave pools thus represent the perfect ground for initial testing of boards and fins and will also be key in the process of validating and advancing the CFD technology by evaluating simulations results based on feelings in the (fresh) water.”

Surfboard Fins

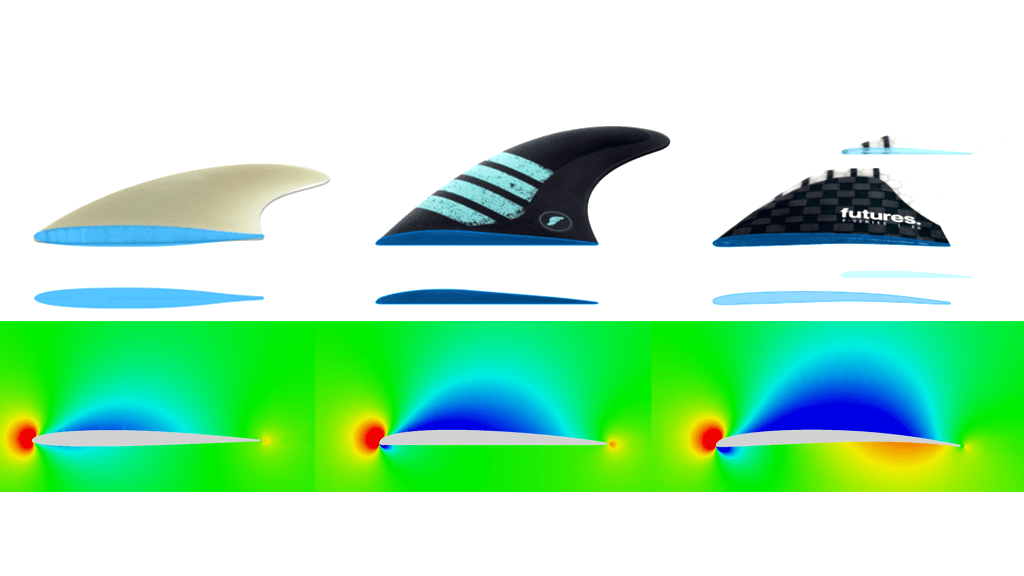

The company’s work to develop a tool able to provide a comparative assessment of performance in a controlled environment is now being embraced by one of the two major fin brands. Vince Longo of Futures Fins says the company started out with just the fin basics, focusing on rake, pivot and neutral templates. But now with CFD modeling via Ricky’s company RED there are more options.

“We started with the CFD to see the differences and obtain a lift-drag profile, along with a map of where the lift and drag occur,” said Vince. “This helped us define when to use a rake template, a pivot template, or a neutral template, primarily at high angles of attack. When running the water over the fin and turning it at high angles, such as 15 to 18 degrees, the lift output was much better for the raked fins. This is how we positioned the rake, pivot, and neutral templates.”

Vince added that the process before was just simple feedback, combined with human alchemy.

“Some team riders I know better than others, so I know that when they say it felt fast, it may mean something different than what another team rider said felt fast,” said Vince. “You know, what John John says is fast different than what Jack Robinson says is fast. And the way they describe it, well, you know, their feelings are different.”

Once FuturesFins had access to the CFD modeling they ran it on fins they were already familiar with, just so they could verify the system. In doing so they made many new discoveries.

“For example, I know this fin is looser, and I know this fin is stiffer in the same exact area, so the lift-drag profile at zero degrees should be the same,” said Vince. “And then we use CFD to show us where in the fin the major part of the lift was coming from. And it was different in each style of fin and the lift was different at different angles of attack in each fin.”

Making Changes

Vince said he used the CFD with Ricky to refine the foils, refine the template and refine the angles in some designs. In the process, they came up with a fin that significantly reduced drag at the end of the turn.

The company plans to run the CFD and then match theory with real-life-feel via wave pools.

“It’s definitely something that we’re going to put in place here in the near future,” said Vince. “We have the Palm Springs one close by to the industry in Southern California. Wave pools are so consistent, so much more than the ocean.”

FuturesFins is based in Huntington Beach. The SoCal coastline from Santa Barbara to the Mexican Border has some of the most well-known surf spots on the planet. Vince, like Ricky, confirmed there are many drawbacks to running tests at Rincon or Lowers.

“You might wait weeks to get the right feedback when testing in the ocean,” said Vince. “In a wave pool you can receive feedback immediately and on a set date. It really makes a lot of sense.”

Related Coverage